Channel Tunnel: Going beneath the Waters

Beneath the waters of the English Channel, lies the world’s largest underwater tunnel. The 50km long Channel tunnel also called as the Euro Tunnel is a railway tunnel that connects the island of Great Britain with mainland France. The channel tunnel has made an enormous difference for the people of France and England as it has helped reduce the travel time between the UK and mainland Europe from 6-7 hrs to 2.5 hrs.

The Channel Tunnel consists of three tunnels running parallel to each other two for the trains and a smaller tunnel for ventilation, manual access, and emergency. The two train tunnels are 7.6m in diameter and are separated by 30m. In between these two tunnels lies the smaller tunnel of diameter 4.8m. The Channel Tunnel has been built at an average depth of 50m below the seabed. The most amazing part is that the digging of the tunnel started simultaneously in England and the Fresh coast which met in the middle without any offsets.

An extensive amount of research work and geological surveys were conducted to get an idea of the rocks beneath the seabed and to select a suitable location for tunneling. Engineers found chalk and chalk marl at approximately 45m below the seafloor. This geological formation is easy to bore through and is impermeable. The next step was to design a water resistant tunnel boring machine (TBM) that could withstand the high pressure. A total of 11 TBM’s were used for the digging purpose six engaged from one side and the remaining from the other side.

The TBMs excavated a huge amount of chalk. The ground conditions at the two ends were not the same. The ground was wetter on the French end as compared to the British end. Thus, on the French side, engineers decided to crush the chalk by mixing it with water and then pumping it out. All the chalk was put behind a specially built dam 37m high. On the British side, engineers build a landscaped platform at the foot of Shakespeare Cliffs near Dover using the same chalk.

The walls of the tunnel had to be covered with concrete which could withstand the pressure of approximately 45m seabed as well as 45m of water above it. Most important, it had to be waterproof. Thus, the tunnel was lined with nearly 1 million concrete sections which had strength more than the concrete used in nuclear reactors and had a minimum lifespan of 120 years. The walls were also supported by castiron segments that were bolted together.

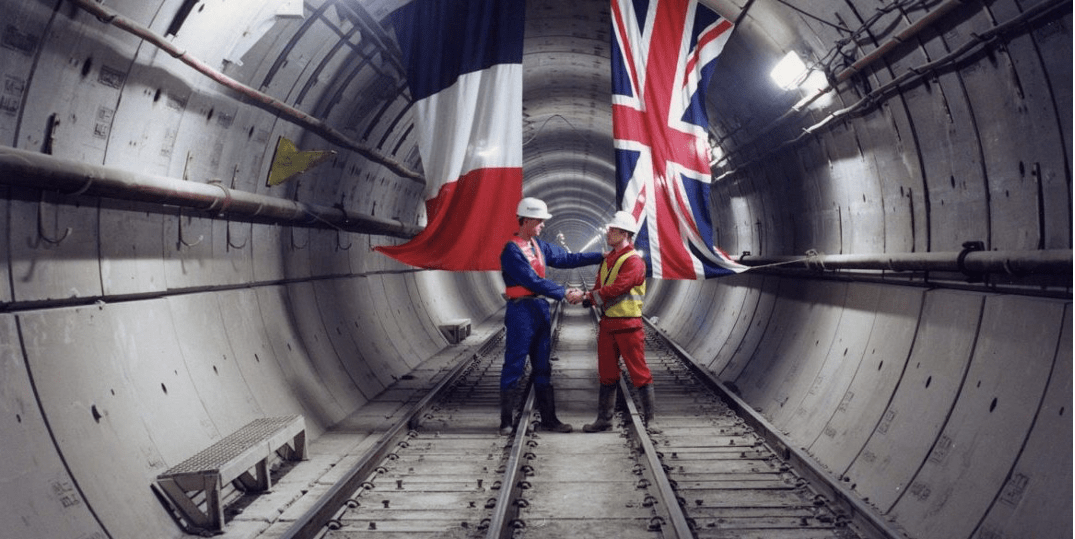

After six years of construction, the tunnel was ready for the first test run on 10th Dec 1993. It was opened for the public on 6th May 1994. The total project cost was around $21 billion. This tunnel is widely regarded as one of the finest engineering feats of this century.

American Society of Civil Engineers calls it one of “Seven wonders of the modern world”